We have considerable experience in prototyping and we offer our know-how to leading manufacturers and industrial operators in the field of aeronautics : prototypes, tailor-made single parts, but also small, medium and large series of parts. We develop and test highly complex parts such as stators. Our strict procedures are based on our expertise and mastering of tool innovation and micro-mechanics. Each individual part reaches a maximum quality level before being integrated into planes, helicopters and other flying vessels such as drones.

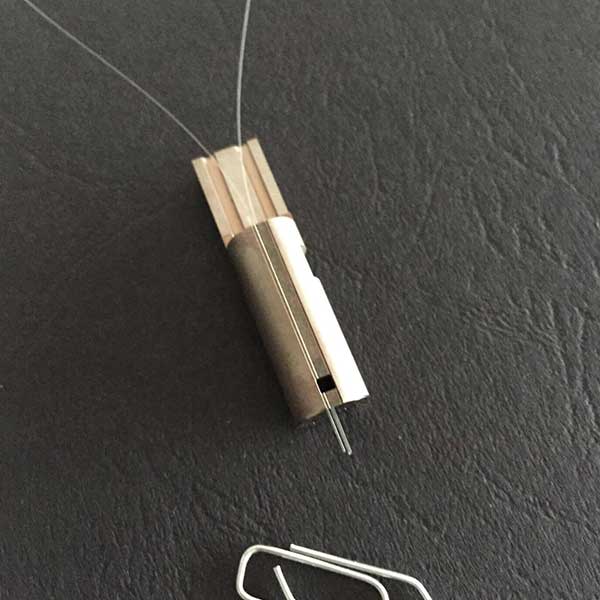

– Electrical Discharge Wire Erosion (water bath)

– wire erosion in oil bath

– electrical discharge die-sinking

– High Speed Milling (3 and 5 axes)

– electrical discharge micro-drilling

– turning

– precision-grinding (flat surface)

– precision-grinding (cylindrical)

– laser marking

– quality control and metrology

– complex mechanical parts from clients’ plans :prototypes and single parts from 1to 10 parts. (total production time from 3 to 4 weeks)

– complex mechanical parts from clients’ plans : small and medium-sized series from 50 to 500 parts. (total production time from 4 to 5 weeks)

– advice/engineering Micro Erosion