An integral part of the corporate culture of Micro Erosion for a long time has been to build teams of engineers from different generations ; the young, and the more experienced. This is an excellent way to exchange knowledge and expertise and to encourage innovation and idea-sharing. Consequently, the team remains motivated and ready for innovation on a daily basis.

The highly specialized, demanding and confidential fields such as aerospace, medical, connecting, watchmaking, energy and automobile are constantly searching for the best possible parts on the market. Micro Erosion has never stopped investing in and acquiring the very latest cutting-edge technology available to meet these requirements.

Florent Boiteux is in charge of the R&D department of Micro Erosion after gaining 15 years of experience as production manager. He is strongly attached to the culture of the company. He has combined his deep knowledge, skills and expertise in the production area with a passion for design and conception, which has helped the company to find pertinent solutions for many projects.

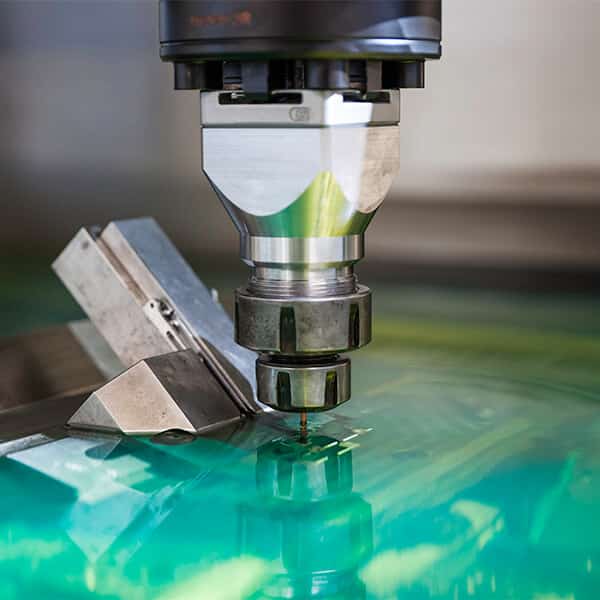

Micro Erosion has it sights set on high performance and has developed impressive expertise and knowledge of the properties of the different types of materials to be machined. These acquired competencies are based on four parametres : metallurgy, mechanics, tribology, and thermal properties. Micro Erosion has scrutinized the plans and constraints of all future parts before they begin to consider the optimal machining methods and tools to complete a project. Machining methods include turning, precision grinding, milling, spark erosion and drilling and they possess a considerable amount of equipment.

Micro Erosion is able to give rapid and sound advice on the best raw materials to use to produce a specific part upon request.

Steel : an excellent cost-effective material which is ,however, sometimes difficult to machine and can cause wear on machine-tools.

Aluminium : this material is light and strong and possesses excellent mechanical and thermal properties.

Brass : this material is relatively easy to machine and has a significant resistance to corrosion. It also leaves a perfect finish and attractive appearance.

Stainless steel : This material is relatively expensive but extremely useful due to its strength and quality.

Titanium : This is one of the most difficult materials to work with and requires experience and expertise. It is, however, light and extremely solid.

These controls ensure that the finished parts are as close to perfection as possible and comply with the plans and demands of the client.

> 3 3D Stereoscopic Microscopes MANTIS

> 1 Camera 4K

> Endoscope

> Vision and sensor measuring machine MicroVu VERTEX 311 UM,

> Measuring machine 3D TESA Micro-Hite,

> Measuring arm TESA,

> Sensor TESA,

> Sensor HEIDENHAIM,

> Column TESA Hite 350+D,

> Projector profile TESA,

> Microscope with digital camera NM1 GARANT,

> Rugosimeter,

> Durometer

“We are permanantely confronted by tough constraints and requirements, so we are now used to dealing with urgent requests, finding specific solutions and developing prototypes. Consequently, we are fully equipped to cater for the production of single parts, medium and larger series. In addition, we are able to work within relatively short timeframes.”

Hélène, Project manager.

Producers of complex parts

Everyone working in the team has been fully trained and possesses great versatility. Together, they have achieved impressive results in terms of performance and have reached a stage where the quality of the finished products is exceptional, including even the most complex of parts.

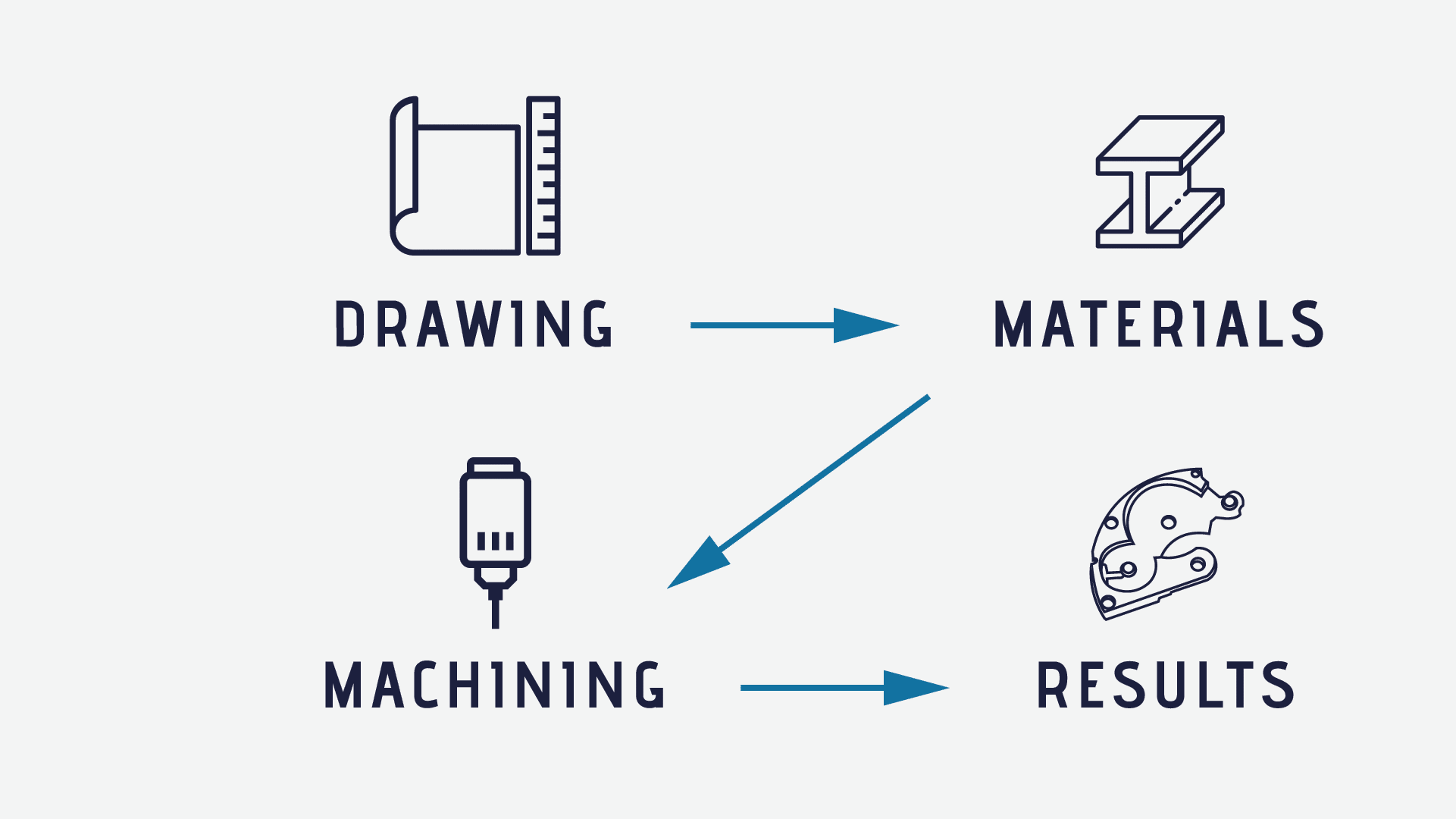

Prototypes and small series of parts ; The procedure for the development of this type of high-added-value part is as follows :

(drawings, materials, forming, result)

“The heart of our company is our people and we are constantly striving to optimize the working conditions of each and every one of our employees. We also work very closely with our clients in order to build an environment of transparency and trust.”

Michelle Laude, accounting Manager.

The domains of aerospace, electronics and watchmaking, amongst others, are fields of activity which need to be worked on with great discretion. Our complete I.T. System is under high and constantly-updated security. All new staff are immediately informed of the company culture which is to keep their work confidential and secret because we work hand in hand with companies that focus on innovation.

working to tolerances of a micron is our domain

Prototypes and small series of complex parts of high added value.

1 – electrical discharge die-sinking

2 – high-speed milling

3 – flat and cylindrical grinding

4 – turning

5 – wire-erosion

6 – R&D, conception, engineering, advice