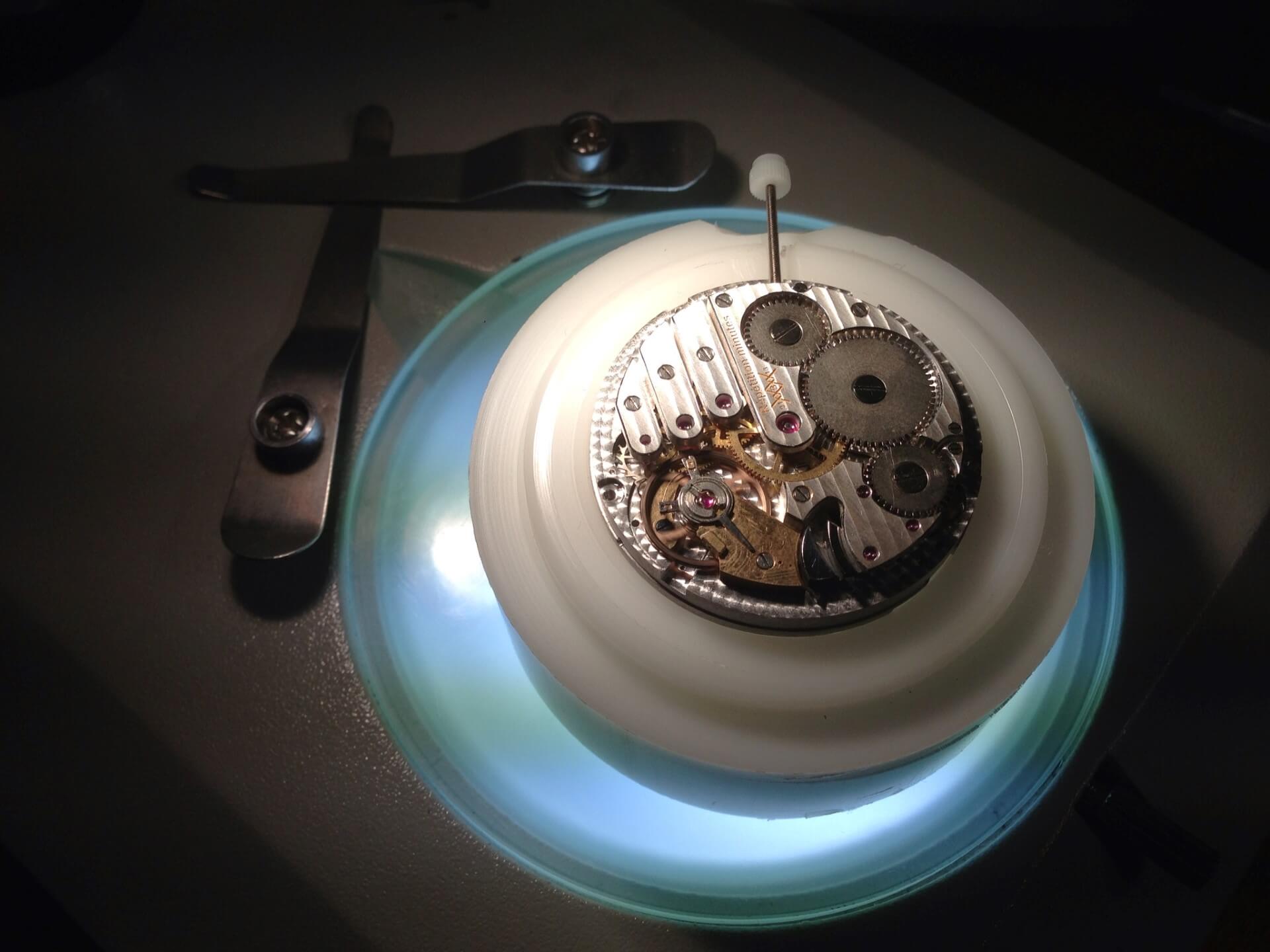

High precision micro-mechanics now play a major role in the fields of watch movements and metals transformation. Watchmakers of high-end products demand extremely high-quality complex parts for their needs. Micro Erosion are committed to meeting the requirements of these new specifications. Our engineers and qualified technicians strive to deliver parts of exceptional precision whether it be a prototype or the production of a series of parts. Examples of parts include : plates, bridges, springs, hands and notably, systems to control the assembly of these parts.

– wire erosion in oil bath

– Electrical Discharge Wire Erosion (water bath)

– electrical discharge die-sinking

– High Speed Milling (3 and 5 axes)

– electrical discharge micro-drilling

– turning

– precision-grinding (flat surface)

– precision-grinding (cylindrical)

– laser marking

– polishing and glass-bead blasting

– quality control and metrology

– complex mechanical parts from clients’ plans :prototypes and single parts from 1to 10 parts. (total production time from 3 to 4 weeks)

– complex mechanical parts with the advice and engineering competencies of Micro Erosion :prototypes, single parts and small series from 1to 10 parts. (total production time from 3 to 4 weeks)

– complex mechanical parts from clients’ plans : small and medium-sized series from 50 to 500 parts. (total production time from 5 to 6 weeks)

– conception, machining and assembly of complex mechanical tools. (total production time from 2 to 5 months)

– advice and engineering from Micro Erosion