« We believe in the new technological progress of our time and are willing to invest in the latest high-precision machines. We have, for example, acquired the Charmilles 2050 TWO in oil with its robot system (3R 12 positions) for our wire-erosion in oil bath. Similarly, for our requirements in the area of electrical discharge die-sinking, we now possess the AgieCharmilles Form 3000 VHP with its robot 3R feeder system. » Benoît Laude, Technical and Developments Manager.

1 AGIECHARMILLES CUT 3000 with divider JauchSchmider,

L500 x l350 x H256

> 1 AGIECHARMILLES 6050 TW, L630 x l400 x H160

> 1 CHARMILLES 4030 SI, L450 x l320 x H240, including one with System 3R rotary tables, 20 positions

> 3 CHARMILLES 2030 SI, L320 x l220 x H116

> 1 rotating Spindle System 3R

> 1 FANUC ROBOCUT ⍺-C400iC, L400 x l300 x H255

> 1 FANUC ROBOCUT ⍺-C400iC, L600 x l400 x H410

> 1 FANUC ROBOCUT ⍺-C400iC, L400 x l300 x H255

This technique enables parts to be be machined for the medical and watchmaking fields as it avoids any surface corrosion of the materials.

> 2 CHARMILLES 2050 TWO in oil with robot System 3R 12 positions, L320 x l220 x H160

> 1 AGIECHARMILLES FORM 3000 VHP with robot System 3R WPT 1+, L600 x l400 x H500

> 1 AGIECHARMILLES FORM 2000 with divider JauchSchmider, L350 x l250 x H350

> 1 AGIECHARMILLES DRILL 20 CN drilling option Ø 0.15 mm,

L300 x l200 x H300

> 1 CHARMILLES DRILL 11 drilling option Ø 0.15 mm,

L300 x l200 x H300

> 1 CASTEK MD 30 CNC drilling option Ø 0.1mm and orbiting

option for calibrate Ø after drilling, L300 x l200 x H330

Machining of series parts.

> 1 BUMOTEC S191 Ø65 7axis, L410 x l200x H400

Machining of parts made of any material.

> 2 MIKRON MILL S 400 U 5 axes spindle 40,000 rpm with System 3R rotary tables, 12 positions,

Tool magazine : 68 tools, L500 x l250 x H360

> 2 MIKRON HSM 400 U 5 axes HSM spindle 42,000 rpm with System 3R rotary tables 48 positions et 18 positions,

Tool magazine : 36 and 68 tools, L400 x l240 x H350

> 1 MIKRON HSM 400 3 axes HSM spindle 42,000 rpm with EROWA 7-position feeder,

Tool magazine : 36 tools, L400 x l450 x H350

Machining of parts on a milling machine CNC.

> 1 Milling center CN SOMAB DIAM 850 L 3 axes spindle 10,000 rpm,

Tool magazine : 24 tools, L850 x l600 x H560

Machining of parts on a CNC.

> 1 SOMAB OPTIMAB 350 V AERO TD 2 axes, Ø 410 x L600

> 1 SOMAB OPTIMAB 350 2 axes + axis C, Ø 410 x L600

Flat and cylindrical grinding on workpieces made of materials such as H.S.S. and tungsten carbide.

Flat grinder

> 1 JONES & SHIPMAN 624 Easy, L600 x l200 x H400

> 1 JONES & SHIPMAN TECHMASTER 634X, L600 x l300 x H605

> 1 JONES & SHIPMAN 540 S, L450 x l150 x H457

Cylindrical grinder

> 1 LIPEMEC RC 250, L250 x l200 x H100

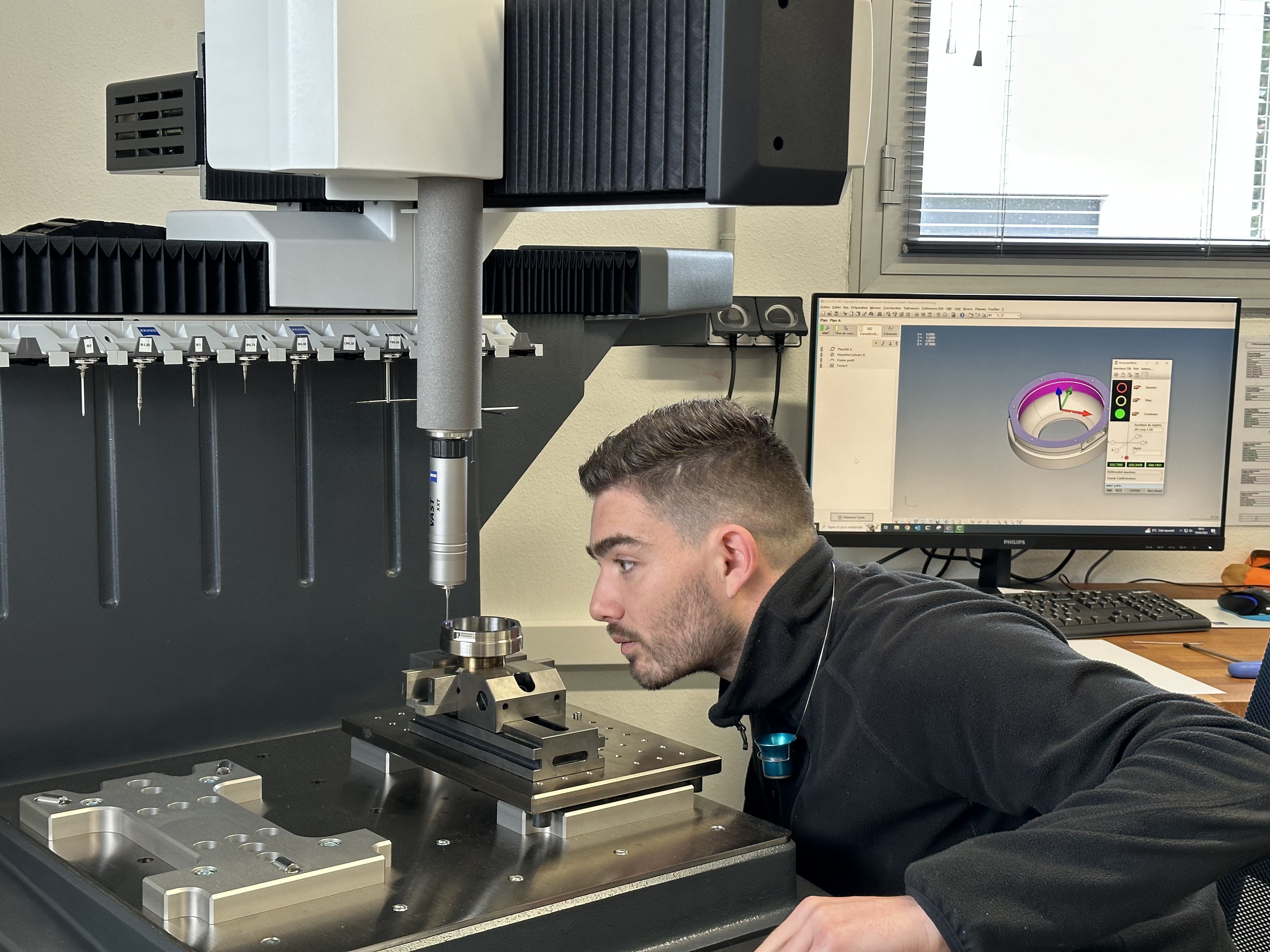

Visual and dimensional control with high-tech equipment.

> 2 Probing machines ZEISS DURAMAX CNC,

> Probing machines and optical ZEIQS O-INSPECT,

> Optical measuring machine MARCEL AUBERT OPTIMUM GL 150,

> MMT TESA Micro-Hite 3D,

> Optical measuring MicroVu VERTEX 311UM,

> Microscope with digital camera MM1 GARANT,

> 2 Stereoscopic microscopes ZEISS Stemi 305,

> 3 Stereoscopic microscopes 3D MANTIS,

> Camera 4K,

> TESA measuring column Hite 350+D,

> Rugosimeter,

> Durometer

> Master pin every 0.1 mm,

> Plastiform

Manual and mechanical polishing up to Ra 0.1

> 1 Line of equipment for polishing parts

> 1 Polishing Machine LAM PLAN MM 8027 Vibratory/Tumble finishing and polishing

FDM technology

> Raised 3D Pro machine,

> Markforged Onyx Pro machine

MSLA technology

> ELEGOO Saturne 2 machine,

> Mercury X Bundle machine

We guarantee the traceability of our parts thanks to laser marking.

> 1 Machine Laser SIC MARKING L-BOX 20W

> 1 Quenching furnace NABERTHERM

Passivation of stainless steel parts mainly for the medical field. This type of surface treatment protects stainless steel from any corrosion.