We have worked with some of the biggest multinational suppliers of energy for a considerable amount of time.We are constantly seeking to improve our operating systems right through all the departments of our company from research and development to the electronic management of all administrative tasks. Our machining and measuring techniques are improving all the time. With 20 years of experience behind us, we are certainly fully-equipped to produce the most demanding high-precision mechanical parts for the energy sector.

– Electrical Discharge Wire Erosion (water bath)

– wire erosion in oil bath

– electrical discharge die-sinking

– High Speed Milling (3 and 5 axes)

– electrical discharge micro-drilling

– turning

– precision-grinding (flat surface)

– precision-grinding (cylindrical)

– laser marking

– polishing and glass-bead blasting

– polishing and glass-bead blasting

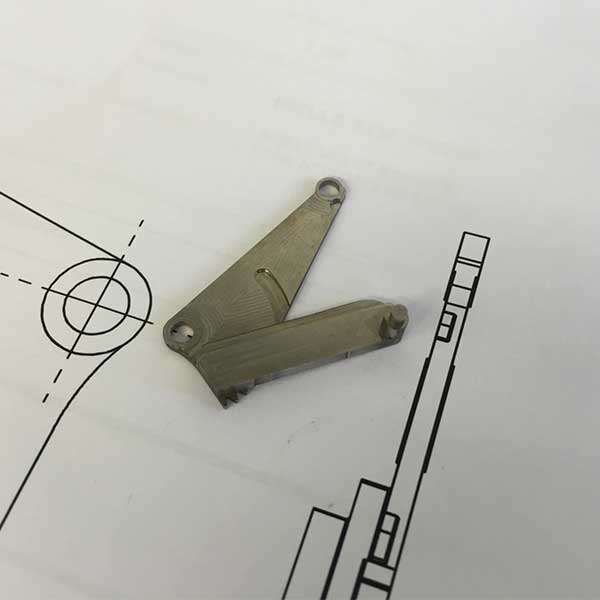

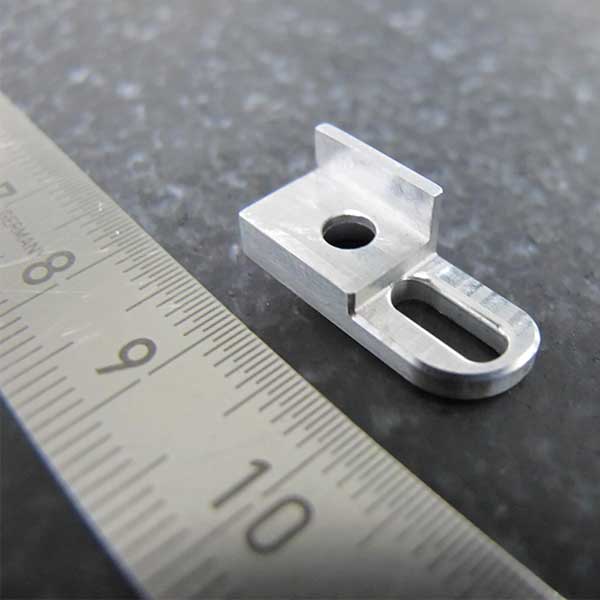

– complex mechanical parts from clients’ plans :prototypes and single parts from 1to 10 parts. (total production time from 3 to 4 weeks)

– complex mechanical parts with the advice and engineering competencies of Micro Erosion :prototypes, single parts and small series from 1to 10 parts. (total production time from 3 to 4 weeks)

– complex mechanical parts from clients’ plans : small and medium-sized series from 50 to 500 parts. (total production time from 5 to 6 weeks)

– conception, machining and assembly of complex mechanical tools. (total production time from 2 to 5 months)

– Advice/engineering Micro Erosion