« We’re banking on major technological advances and investing in high-precision machinery. This applies to both production and inspection equipment. » Benoît Laude, Technical and Developments Manager.

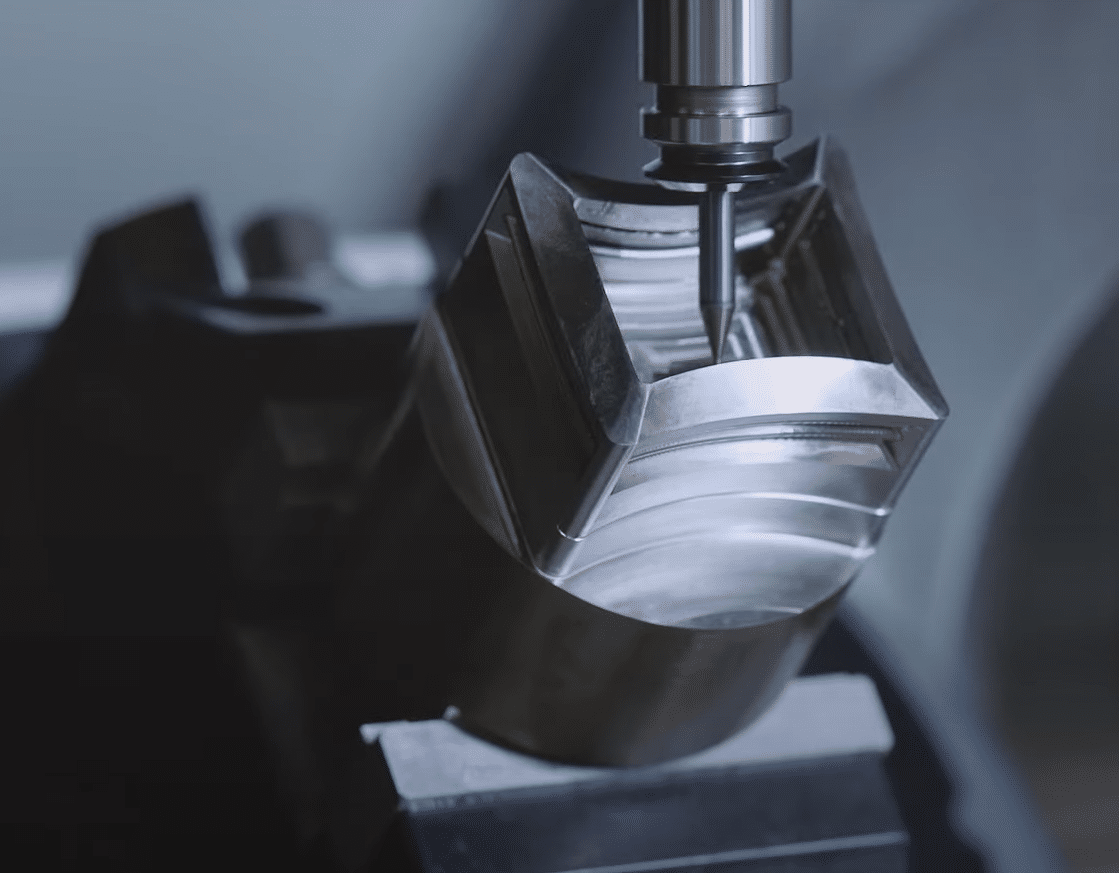

Machining in all types of materials :

– Titanium

– Steel

– Aluminium

– Stainless steel

– Copper

– Brass

Bar feeder up to 65 mm diameter.

Specialised machines for mass production.

Machining on CNC machines.

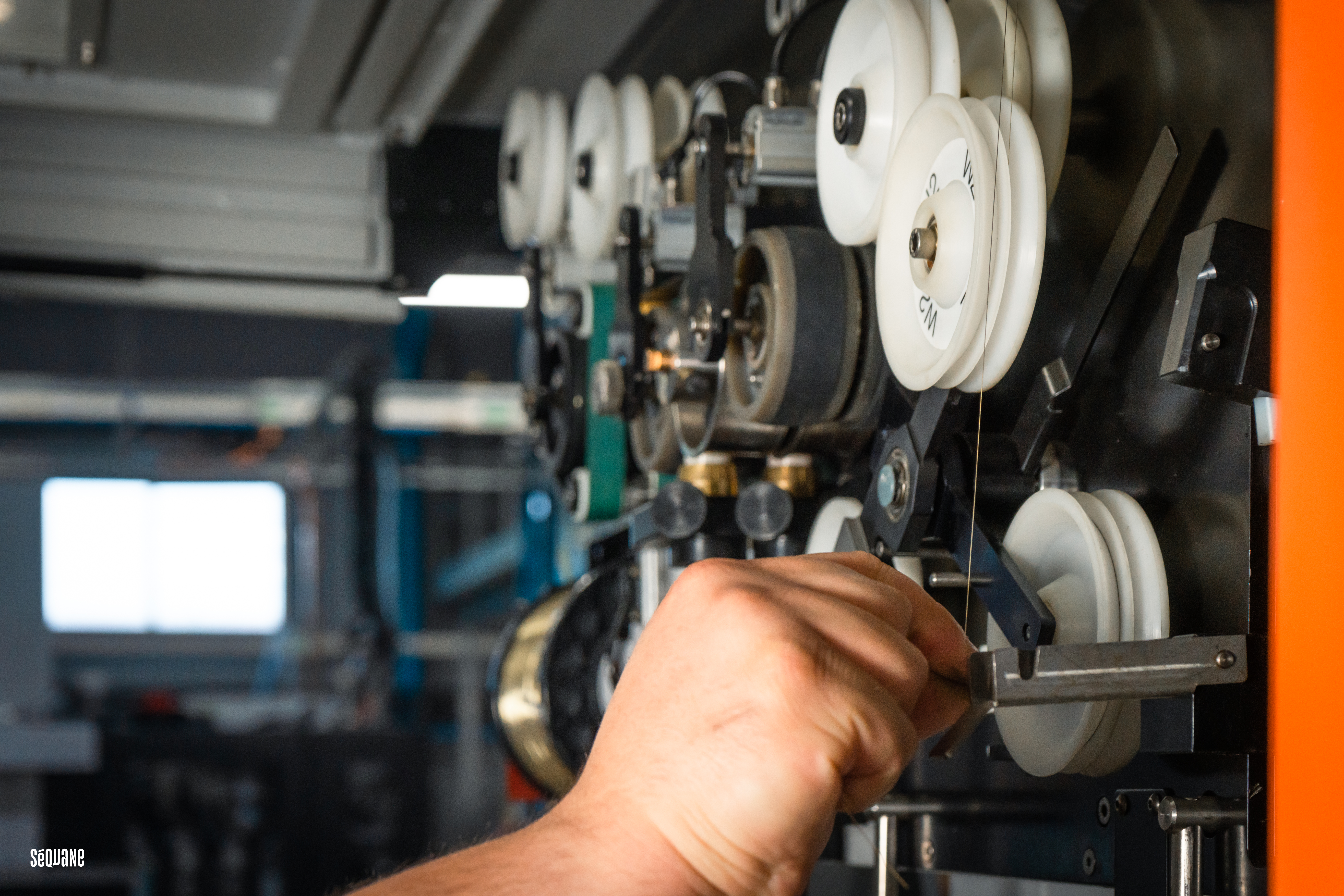

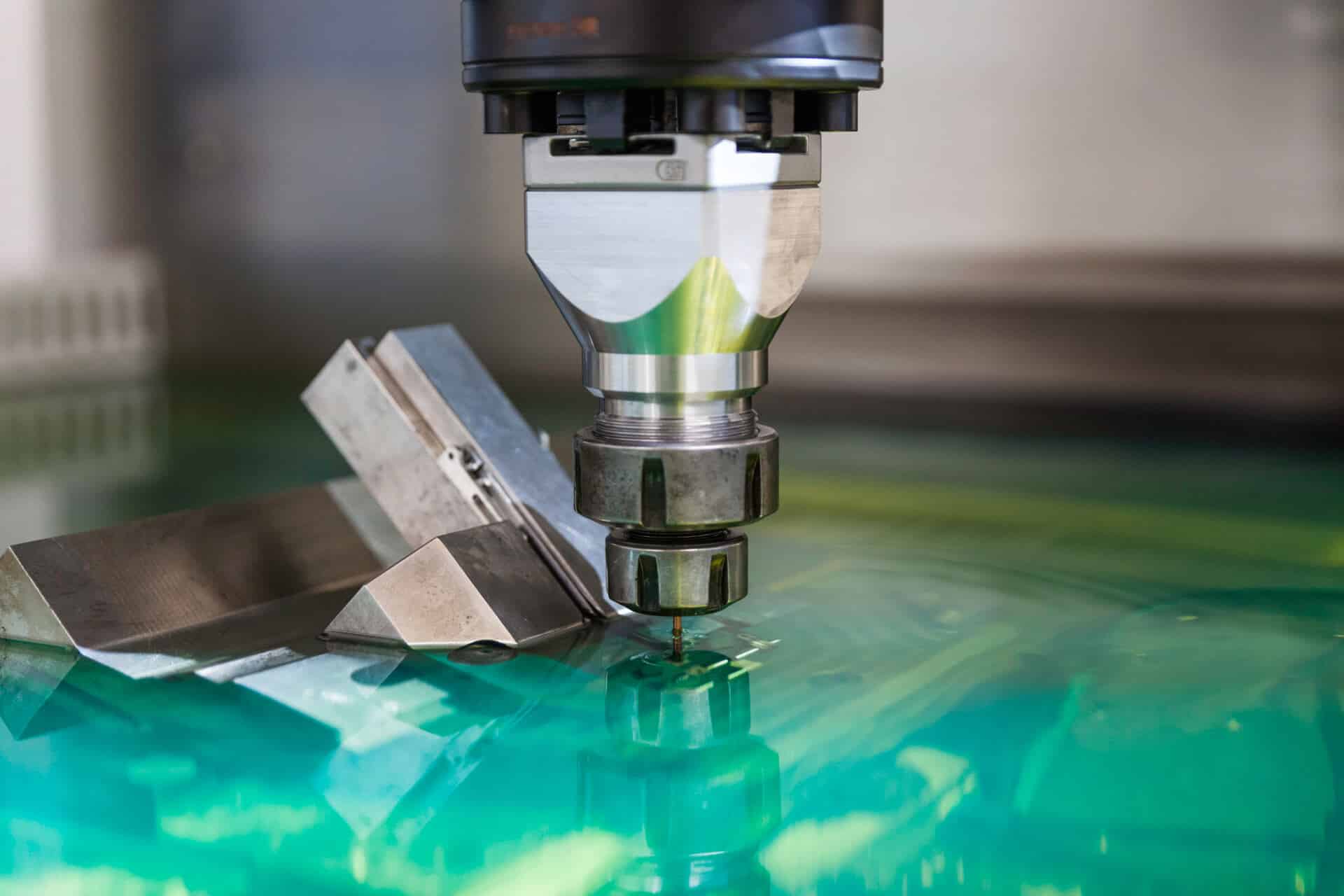

Electrical Discharge Wire Erosion in oil bath

This technology makes it possible to machine parts for the medical and watchmaking industries without corroding the materials.

We have developed Molybdenum wire EDM for the space and medical sectors.

Flat grinding of steel and tungsten carbide parts.

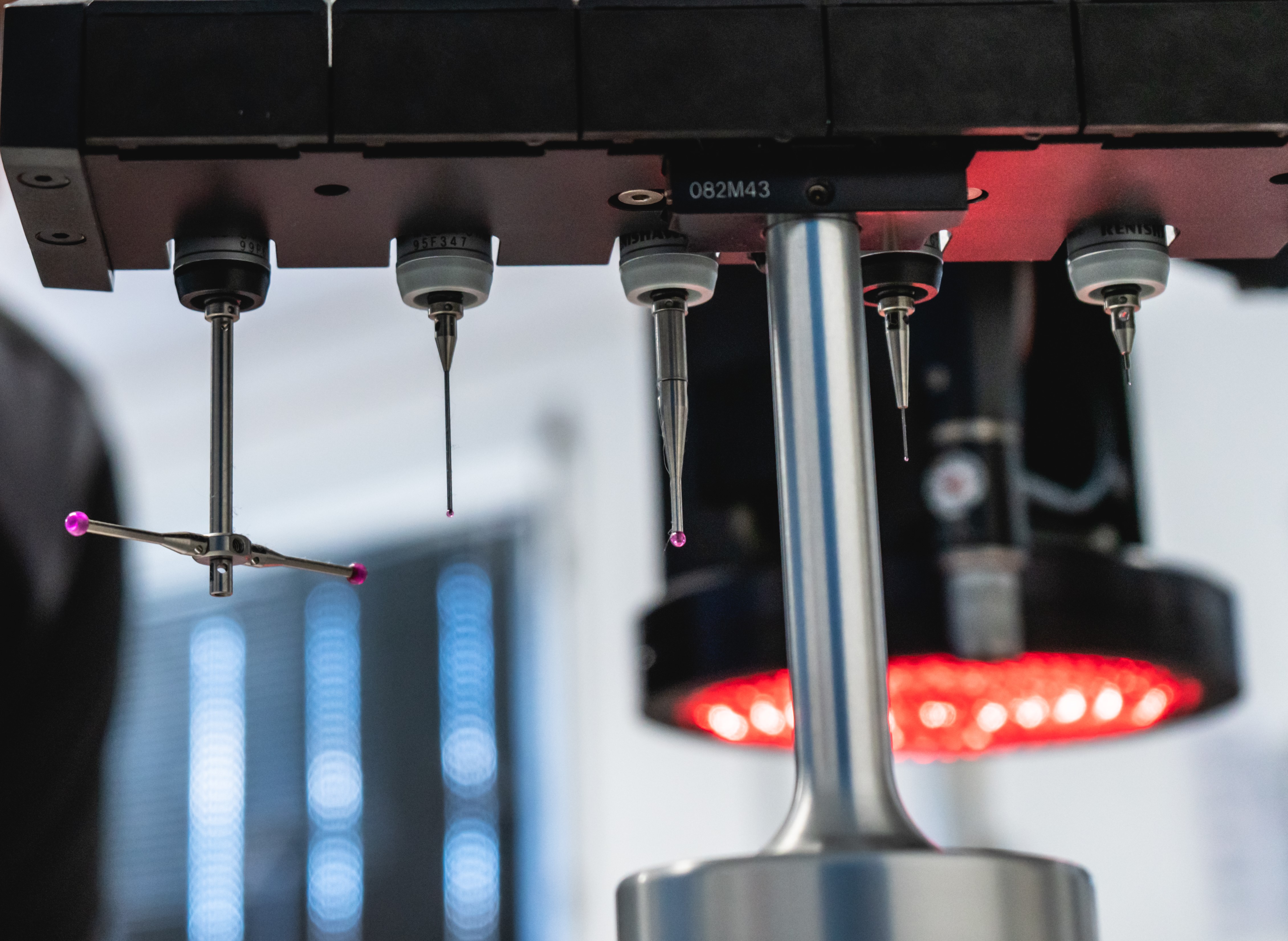

Visual and dimensional control with high-tech equipment.

– Probing machines ZEISS,

– Probing and optical machines ZEISS,

– Optical measuring machine MARCEL AUBERT,

– Non-contact roughness measurement machines BRUKER ALICONA,

– MMT TESA Micro-Hite 3D,

– Optical measuring MicroVu VERTEX,

– Microscope with digital camera MM1 GARANT,

– Stereoscopic microscopes ZEISS,

– Stereoscopic microscopes 3D MANTIS,

– TESA measuring column Hite 350+D,

– Rugosimeter,

– Durometer

– Master pin every 0.1 mm,

We have a line of equipment for finishing parts.

We use laser marking to ensure the traceability of our parts, with specific parameters for the medical sector.

Passivation of stainless steel parts mainly for the medical field. This type of surface treatment protects stainless steel from any corrosion.