E.D.M. (Electrical Discharge Machining) involves the removal of metal from a workpiece by sending an electric current through an electrode or wire. The principle is the same for wire erosion, die-sinking and micro-drilling. This technique ensures perfection in terms of dimensions and surface finish regardless of the type of metal being machined.

Once a micro-hole has been drilled, the wire can be passed through the workpiece and the erosion of the metal can take place. This type of extremely high-precision machining is perfect for prototypes,single parts and medium-sized series. Furthermore, this process does not leave any shavings. The finished parts are then integrated into special machines or as part of other complex assemblies. The parts can be fitted together either within Micro Erosion or in the client’s company. The entire machine park is digitally controlled and both wire erosion oil-bath machines are robotised. These robots are equipped with a 10 position feeder.

Wire Erosion : a live wire is set to move in specific directions and angles and cuts the workpiece, which is adjusted and held in position. The workpiece is permanently immersed in either a special dielectric oil bath or a deionised water bath. These liquids are continually filtered.

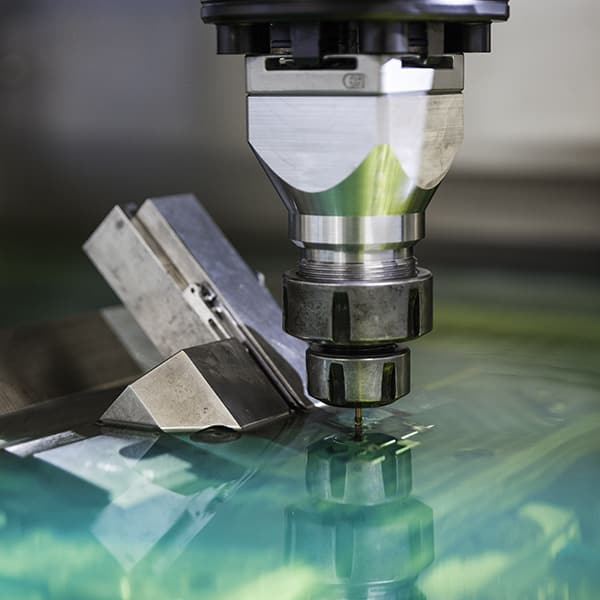

Die-Sinking : an electrode, which has been previously machined to the required shape, is lowered into the workpiece and erodes the material to the correct size and complex shape.

High Speed Drilling : similar to die-sinking, this technique uses a tubular electrode which is able to drill through particularly hard materials.

– high precision machining.

– machining of pre-tempered parts.

– machining of ultra-hard metals such as tempered steel and carbides.

– Ability to produce parts of any shape.

– Excellent surface finish (Ra)

The parts to be machined must be electrical conductors such as steel, titanium,carbides, stainless steel, titanium, tungsten carbide.

–wire erosion in water bath

Micro Erosion work with companies in specialized sectors such as medical, connecting, aeronautics, energy, automobile, watchmaking and luxury goods.

– Wire erosion in oil bath

Their main clients are from the fields of medical equipment, watchmaking and luxury goods. They also produce high-precision parts for connecting, aeronautics, energy and automobile sectors. This machining process guarantees zero corrosion, high precision and a surface finish which has an extremely low roughness index (Ra).

– Electrical discharge die-sinking

Their main clients are from the fields of medical, connecting, aeronautics, energy, automobile, watchmaking and luxury goods.

Micro Erosion design their own electrodes which sink into the workpiece by electrical discharge and form any number of complex shapes. This process is often required when a part has a cavity rather than an actual hole going through it.

The electrodes are designed and developed in-house in their R&D department.

“By using relatively slow machining speeds, (0,2 to 10mm /min), the end results are very impressive in terms of precision and quality. Furthermore, dimension tolerances are incredibly tight (maximum difference of 2 microns from specified dimension).”