Clinching is used to join thin sheet metals (flat or shaped) together mechanically and displays a high quality of resistance and solidity.

The two or three layers of different metals are press-fitted together (without heat) thanks to a precise localised deformation of these metals. This is achieved by using high-precision tools equipped with punches and matrices.

This process does not deteriorate the surface of the metal, which is extremely beneficial, and can be used to join many types of metal such as stainless steel, alloys, lacqered metal or metals previously painted or coated with plastic.

Clinching does not involve any type of welding techniques ; it is purely mechanical.

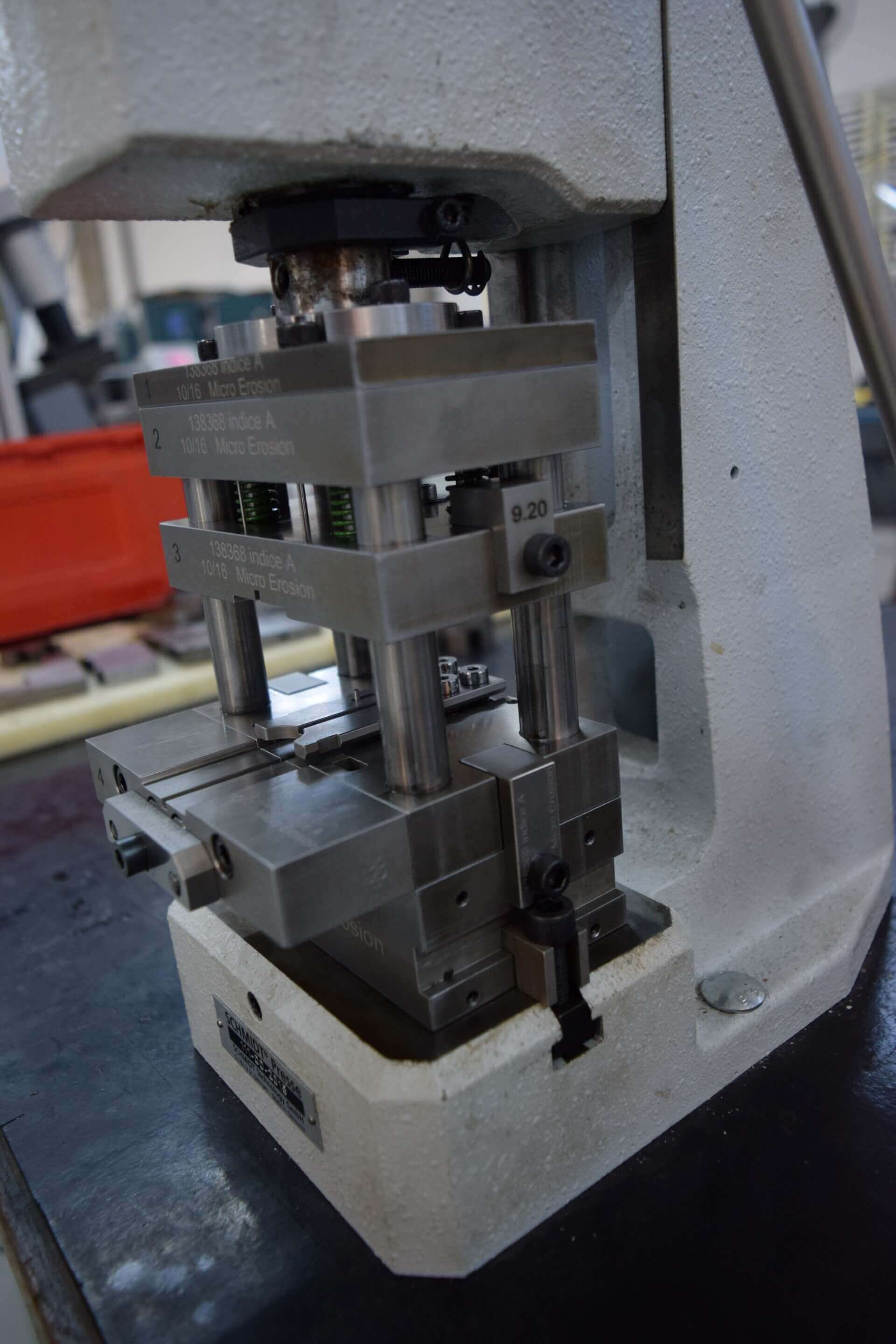

Micro Erosion have developed complex tooling systems equipped with sub-assemblies that result in accurate, high- precision clinching.

The in-house R&D department of the company have designed a compact clinching tool for ultra-thin blade-fuses made of copper and silver. There is no deformation of the fuse.

– No adhesives used

– No joining materials

– No bolts or rivets

– No welding spots

– No heat used

– No deformation of the materials assembled

– Reliable process

– Cost-effective

– Environment-friendly

“The knowledge gained from this fuse-blade project can obviously be applied to other types of sheet metal. We have significantly strengthened our know- how concerning the handling of copper and silver.”