For several years, Micro Érosion has been actively pursuing a policy of social responsibility within a team intentionally composed of qualified engineers and technicians from different generations.

Knowledge transfer occurs naturally, and the resulting dynamic fosters daily motivation while cultivating a mindset of anticipation and innovation.

The continuous acquisition of high-tech equipment enables us to stand out and successfully meet the demanding requirements of cutting-edge markets such as implantable medical devices, aeronautics, space, connections and luxury.

With over 20 years of expertise, we have successfully developed large-scale projects by providing tailored advice and custom solutions.

Our know-how covers machining technologies, processes, materials, and treatments, allowing us to deliver responses precisely aligned with our clients’ needs.

Project tracking and management are a top priority for us, with regular progress reviews to ensure optimal outcomes.

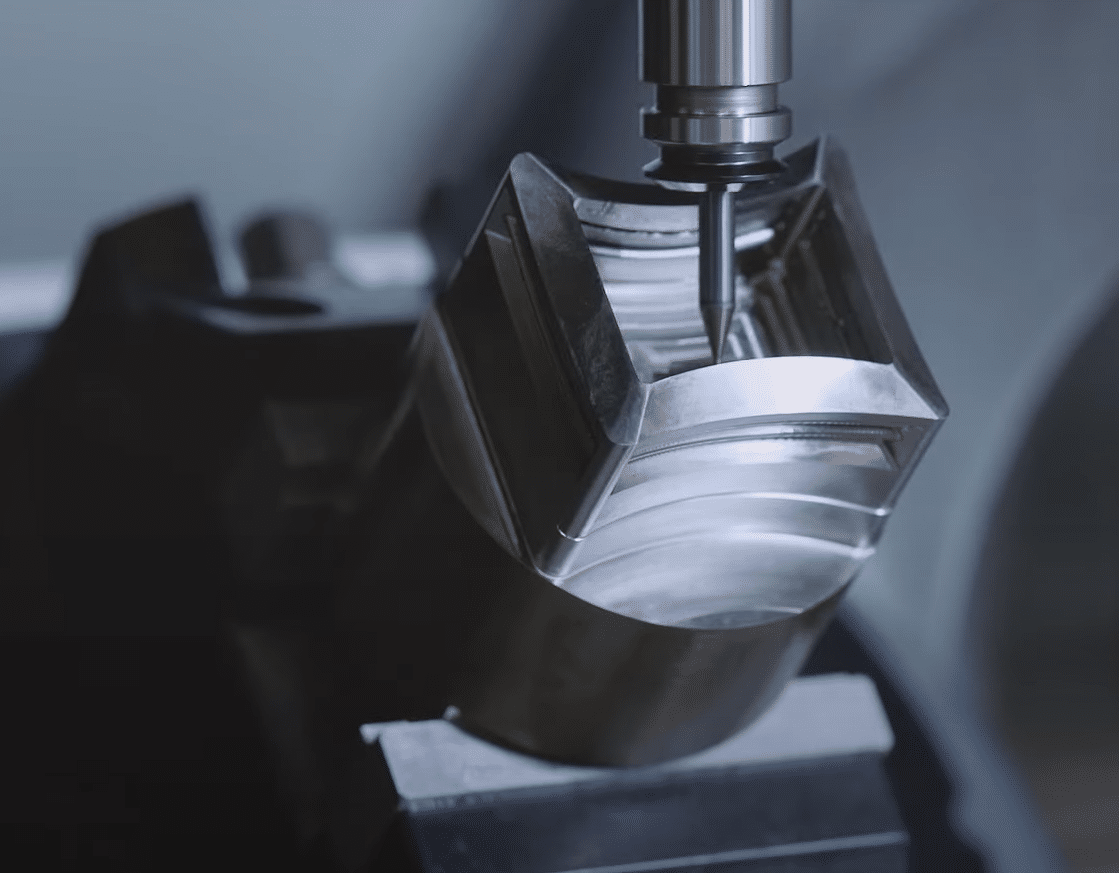

At Micro Erosion, this is our core expertise. Producing complex parts requires an approach that combines consultancy and engineering. To achieve this, we have an integrated design office and high-performance technologies at our disposal.

High-Precision mechanical and micro-mechanical complex parts for the following domains :

– Medical

– Medical implantable

– Aeronautics

– Space

– Connections

– Luxury

Production times are between 3 and 5 weeks.

Precision machining, milling, turning-milling, turning, wire and die-sinking EDM, flat grinding, machining of hard materials, drilling, threading, deburring, passivation, laser marking, polishing, …

Micro Érosion is at your service to advise you on material selection in order to optimize the manufacturing of your parts.

Titanium: corrosion-resistant, low thermal conductivity, excellent mechanical strength, lightweight, and biocompatible. Although very hard, titanium is difficult to machine and requires advanced technologies and specialized tools for precision machining.

Steel: a cost-effective material by nature, steel remains complex to machine due to its hardness, which can vary depending on its carbon content and applied heat treatments. Certain types, such as hardened steel, offer high wear resistance but can be particularly challenging to machine.

Stainless Steel: appreciated for its corrosion resistance, stainless steel is highly valued for its quality and outstanding durability.

Aluminum: lightweight and known for its mechanical and thermal properties, aluminum is one of the most machinable alloys, making it ideal for many applications.

Brass: durable and wear-resistant, while remaining relatively easy to machine. It also offers excellent corrosion resistance and a high-quality aesthetic finish.

Copper: durable and wear-resistant, making it suitable for long-term applications. A passivation treatment can enhance corrosion resistance and further extend its lifespan.

Tungsten Carbide: an extremely hard ceramic material, highly resistant to wear and heat. Mainly used in cutting tools and industrial applications, it combines hardness, toughness, and durability—making it a preferred choice in demanding environments.

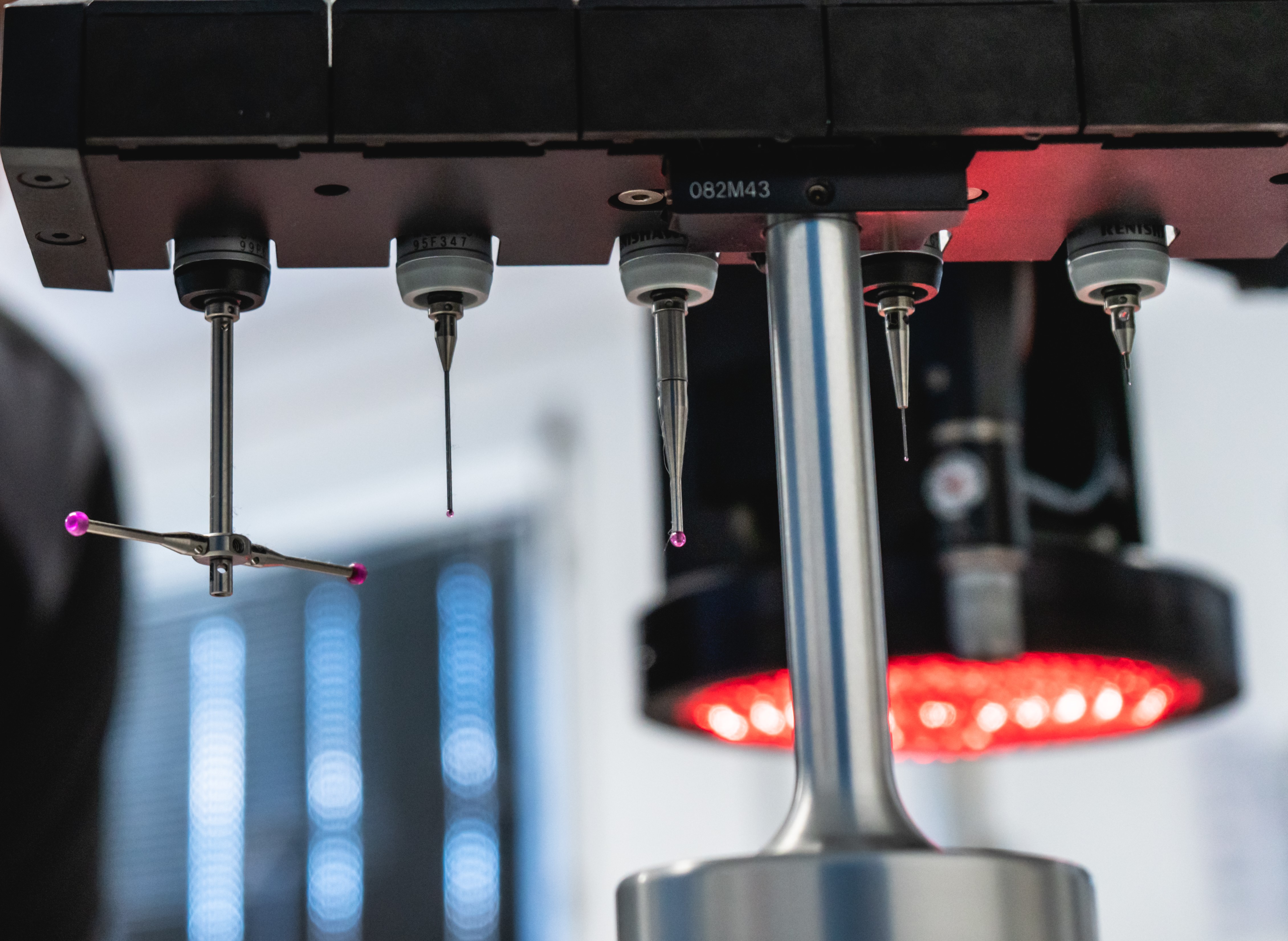

Our technicians carry out inspections throughout the production process by performing their own self-checks.

Final inspection ensures product release while guaranteeing compliance with our customers’ requirements.

To achieve this, we regularly invest in state-of-the-art measuring equipment:

– Coordinate Measuring Machines (CMM) with automated measurements,

– Optical and Touch-Probe Measuring Machines with automated measurements,

– Optical Measuring Machines,

– Non-contact Surface Roughness Measuring Machines,

– Vision Measuring Systems,

– Microscopes with digital cameras,

– Stereoscopic Microscopes,

– Height Gauges,

– Pin gauges in 0.01 mm increments.

“We are permanantely confronted by tough constraints and requirements, so we are now used to dealing with urgent requests, finding specific solutions and developing prototypes. Consequently, we are fully equipped to cater for the production of single parts, medium and larger series. In addition, we are able to work within relatively short timeframes.”

Hélène, Project manager.

Producers of complex parts

Everyone working in the team has been fully trained and possesses great versatility. Together, they have achieved impressive results in terms of performance and have reached a stage where the quality of the finished products is exceptional, including even the most complex of parts.

“The heart of our company is our people and we are constantly striving to optimize the working conditions of each and every one of our employees. We also work very closely with our clients in order to build an environment of transparency and trust.”

Michelle Laude, accounting Manager.

Small, medium, and large production runs of high value-added complex parts.

5-axis milling

7-axis turn-milling

Turning

Wire EDM

Die-sinking EDM

High-speed drilling

Surface grinding